Pizza Ovens That (Almost) Never Cool Off

A modern Neapolitan pizzaioli tends an old-fashioned Neapolitan pizza oven. (Photo: Glenn MacLarty/Flickr)

Humans have basically always loved pizza. The ancient Egyptians ate flatbread with toppings. The 5th century Greek historian Herodotus archived a few good recipes, and the soldiers of the First Persian Empire built cheese-and-date personal pies on their shields, and left them to bake in the sun. These days, American pizza alone is a $35 billion industry. And purveyors of the traditional Neapolitan pizza have a unique preparation method that hasn’t changed in hundreds of years.

They battle every day with an ancient technology—the tempestuous, scorching-hot, almost-always-on wood-fired pizza oven.

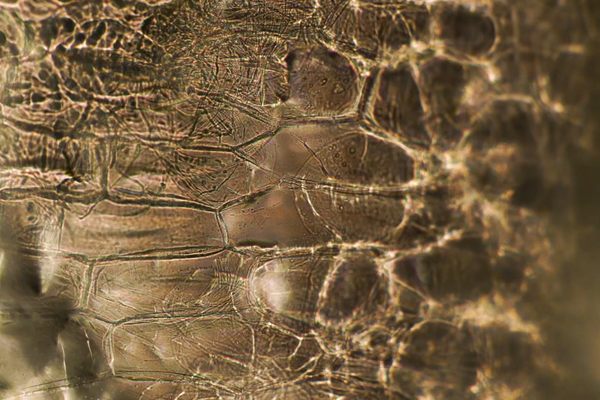

According to the experts at Forno Bravo, it was the Romans who perfected the “modern” pizza oven, with its brick walls, tile floor, domed chamber, and arched front door. (We also haven’t diverged much from ancient Roman pizza shop design, which included granite counters, salad bars, and drink stations.) When the fire is stoked, this type of oven heats the pizza on all sides, which means a quick cooking time that sears the outside and nukes the toppings, but leaves the inside nice and doughy.

A wood-burning oven excavated from ancient Pompeii. (Photo: Polykarbon/WikiCommons CC BY-SA 3.0)

Though some historians disagree, most pizza experts place the birthplace of modern pizza in Naples. Beginning in the 16th century, that city’s peasants and “careless youth“ snacked on flatbread slathered with sauce and cheese and studded with anchovies and garlic cloves. These pizzas were often sold by street vendors called pizzaioli, who baked their pies in central locations that had the dough and space for a big oven—like Antica Pizzeria Port’Alba, widely considered the first pizzeria, and still slinging crusts today. In a familiar progression, what was once a working class staple gained patrician cachet thanks to hungry travelers, and soon royalty was in on the game. According to Carol Helstosky’s Pizza: A Global History, Ferdinand IV, who reigned over Naples from 1751 to 1825, had a pizza oven installed in the garden of his summer palace, after which many lesser aristocrats followed suit.

Soon after, immigrants from Naples began replicating their favorite foods in the U.S.. Styles diverged—think of Chicago deep dish, pineapple, and Kit Kats—the traditional Neapolitan pie, fired in the traditional Neapolitan way, remained. The nonprofit “Associazione Verace Pizza Napoletana,” or “True Neapolitan Pizza Association,” has dedicated itself to “promoting and defending” the subspecies by handing out official designations, like some sort of saucy mafia.

This handcrafted pizza oven in Amsterdam looks like a fire-eyed stormtrooper. (Photo: Holysloot22/WikiCommons CC0 1.0)

Achieving perfection requires good ingredients, careful preparation—and replicating Italy-worthy cooking conditions, something many pizza chefs are almost pathologically committed to. Just as a regular chef might bring her favorite knife set along from job to job, a truly dedicated pizzaiolo often brings his oven. The first (documented) commercial pizza oven in America, which the New York Times calls a “magnificent conglomeration of black-and-white enameled bricks on the outside and terra cotta bricks on the inside,” was first fired in 1905. It belonged, and still belongs, to Lombardi’s Pizza, which trucked it from 53 ½ to 32 Spring Street when they moved down the block in 1994. In the same Times profile, written in 1956, Gennaro “Don” Lombardi himself “patted the oven and said, ‘this is what made me a man today.’” Decades later, succeeding Lombardi generations have matching bald spots and burn scars from taming the beast.

Pizza shops that haven’t been around for centuries try to keep up in their own ways. Some import the goods straight from Naples, lately often from Stefano Ferrara, a third-generation oven-builder whose handmade wares look like colorful igloos. In 2009, Brooklyn’s Paulie Gee brought in one of the first in the U.S., custom-built by Ferrara so that it could slide right into a shipping container. Between transport, customs, installation, and the oven itself, he paid $25,000 for it. “Considering it is the one thing that I absolutely need in my restaurant, it was a bargain,” he told Eater; a few years later, he flew out Ferrara himself to fix the oven in his new Baltimore location. Cooks at New York’s Donatella restaurant refer to their oven as “her,” like a ship, while Boulder’s Pizzeria Locale tried to build their own onsite, using a shipment of clay and Vesuvian ash. Customs shut down that plan, so they had one rerouted from Moscow, and now are attempting to develop a futuristic “gas-and-infrared-powered rotational oven” to help with their planned Chipotle-sponsored expansion.

A Neapolitan pizza of the Margherita persuasion. Note the thin crust, char spots, and lack of slices. (Photo: N Wong/Flickr)

Once they get to their destinations, these behemoths need more tending. When asked about care and keeping, Stefano Ferrara installer Michael Fairholme details the “very prescribed five-to-seven-day process” of slow heating necessary to sweat out the 16 liters of water that, if left in, would crack the brick and tiles. After that, chefs can take it up to a thousand degrees—the temperature required to give pies the perfect ratio of smoke, crisp and chewiness—but that process, too, takes time, about two days for an oven revving up from zero. To stay that hot, it must be fed more fuel at least once per hour. Luckily, cooling is also slow, and an oven left alone overnight is still at 450 when everyone comes in to roll the dough the next morning.

This means the world is full of hungry, temperamental fire caves cycling between “hot enough to roast potatoes” and “hot enough to break aluminum”—all to keep those cheesy, crusty discs flying. Prego.

Gastro Obscura covers the world’s most wondrous food and drink.

Sign up for our regular newsletter.

Follow us on Twitter to get the latest on the world's hidden wonders.

Like us on Facebook to get the latest on the world's hidden wonders.

Follow us on Twitter Like us on Facebook